If you’re looking for a reliable panel manufacturing company, or you’re simply curious about how electrical panels are made, you’re in the right place.

At PIMA Industrial, one of the best panel manufacturers in Ahmedabad, we know that not everyone comes from an engineering background. That’s why this guide is written in plain, simple English—to help you understand panel manufacturing from the ground up.

Whether you’re a business owner, a facility manager, or just someone doing research before investing, this guide will clear up your questions and give you the clarity you need to make smart decisions.

What Is Panel Manufacturing?

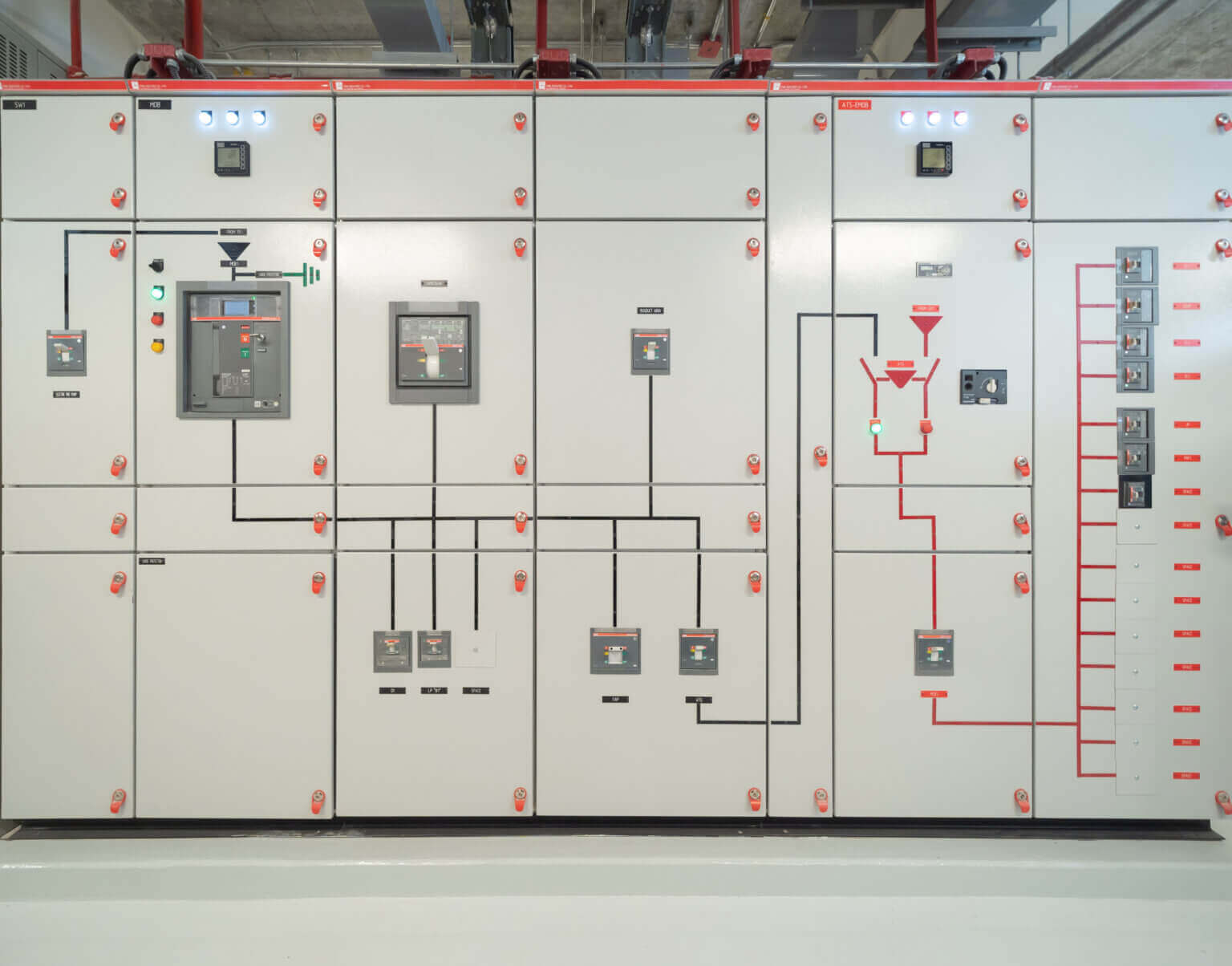

Panel manufacturing is the process of designing, building, assembling, and testing control panels used in electrical systems.

These panels are the heart of electrical distribution and automation in industries, commercial buildings, and even residential setups. They house the circuit breakers, relays, PLCs, contactors, switches, and wiring that control and distribute electricity safely and efficiently.

In simpler terms, a control panel is like the brain of an electrical system.

Why Is Panel Manufacturing So Important?

Without panels, electrical systems would be messy, dangerous, and nearly impossible to manage. Here’s why panel manufacturing plays a crucial role:

-

Safety: A properly manufactured panel prevents electrical accidents.

-

Efficiency: Organizes wiring and components to improve performance.

-

Scalability: Makes it easier to expand your system as your operations grow.

-

Customization: Tailored to specific industry needs, whether it’s automation, HVAC, or power distribution.

Types of Panels Manufactured

Different applications require different kinds of panels. Here are the most common types:

Power Control Center (PCC) Panels

Used for power distribution and control of large motors and equipment. Ideal for factories and large-scale plants.

Motor Control Center (MCC) Panels

Helps manage and control multiple electric motors from a single location. Widely used in manufacturing and water treatment plants.

Automation Panels (PLC/DCS)

Used for process automation in industries. These contain PLCs (Programmable Logic Controllers) that make automated decisions based on logic programming.

APFC Panels

Stands for Automatic Power Factor Control. Helps save energy and reduce electricity bills.

Synchronization Panels

Used to balance load between multiple generators or power sources, ensuring smooth operation without overload.

Step-by-Step Panel Manufacturing Process at PIMA Industrial

At PIMA Industrial, we follow a tested and reliable process to ensure top-quality panels every time.

1. Requirement Analysis

We start by understanding your exact needs—load capacity, type of control, space constraints, and compliance requirements.

2. Design & Engineering

Our expert engineers create a custom panel layout using CAD software. Every component is carefully selected for performance and durability.

3. Material Procurement

Only certified, high-quality materials are used—from branded circuit breakers to industrial-grade enclosures.

4. Assembly

Technicians assemble components on mounting plates and wire them as per the design. Every wire is labeled for clarity.

5. Testing

Every panel goes through multiple rounds of testing—continuity, insulation resistance, and performance under load.

6. Quality Check & Dispatch

After final checks, the panel is safely packaged and dispatched to your site, ready for installation.

Why Choose PIMA Industrial as Your Panel Manufacturer in Ahmedabad?

Choosing the right panel manufacturer isn’t just about price—it’s about safety, reliability, and after-sales support.

Here’s what makes PIMA Industrial the best panel manufacturer in Ahmedabad:

-

✅ 20+ Years of Experience

-

✅ ISO-Certified Manufacturing Process

-

✅ 100% Tested Panels

-

✅ Custom-Built to Fit Your Needs

-

✅ After-Sales Support & Maintenance

We’ve served over 500 clients across industries—textiles, chemicals, pharma, food processing, and more.

Benefits of High-Quality Panels from a Trusted Panel Manufacturing Company

-

Lower Downtime

Reliable panels reduce breakdowns, helping you save on repairs and lost productivity. -

Improved Safety

Panels made with proper insulation and spacing prevent short circuits and fire hazards. -

Energy Efficiency

Smart panel designs can help reduce power wastage. -

Future-Proofing

Easily scalable and upgradeable panels mean you won’t have to start from scratch as your needs grow.

Current Trends in Panel Manufacturing

The panel manufacturing industry is evolving fast. Here are a few trends that smart businesses are following:

-

Smart Panels: Integration with IoT for remote monitoring

-

Compact Designs: Space-saving enclosures with modular features

-

Eco-Friendly Materials: Use of recyclable and lead-free components

-

AI Integration: Predictive maintenance using AI analytics

Staying updated with these trends gives your business a competitive edge.

Signs You Need to Upgrade Your Electrical Panel

-

Frequent circuit trips or overloads

-

Visible signs of burning or sparking

-

Outdated design with no room for new additions

-

Inability to meet growing power demands

If you’re facing any of these issues, it might be time to contact a reliable panel manufacturer in Ahmedabad—like PIMA Industrial.

How to Choose the Right Panel Manufacturer

Here are a few things you should always check:

-

✔️ Proven industry experience

-

✔️ Use of certified components

-

✔️ Testing and quality assurance

-

✔️ Custom design capabilities

-

✔️ Client references or case studies

-

✔️ On-time delivery record

When you work with PIMA Industrial, you get all this and more.

Common Industries That Need Panel Manufacturing

-

Manufacturing

-

Pharmaceutical

-

Textile

-

Food Processing

-

Chemical Plants

-

Hospitals

-

Commercial Buildings

-

Data Centers

Every one of these industries relies on high-quality, durable control panels to function safely and efficiently.

FAQs About Panel Manufacturing

What is panel manufacturing and why is it important?

Panel manufacturing is the process of designing and building electrical control panels. It’s crucial for safe power distribution and automation in various industries.

Who needs panel manufacturing services?

Industries like manufacturing, healthcare, pharma, and construction all need reliable panels to operate safely and efficiently.

Where can I find the best panel manufacturer in Ahmedabad?

PIMA Industrial is widely regarded as one of the best panel manufacturers in Ahmedabad, known for its quality, reliability, and customer service.

How long does it take to manufacture a custom panel?

It usually takes 2–4 weeks, depending on the complexity and specifications of the panel.

Why should I choose a certified panel manufacturing company?

Certified manufacturers like PIMA Industrial ensure compliance, safety, and performance, reducing your long-term operational risks.

Will my panel be tested before delivery?

Yes, every panel is tested thoroughly at PIMA Industrial before dispatch to ensure it meets all performance and safety standards.

How do I maintain my control panel?

Regular inspections, cleaning, tightening of connections, and thermal scanning are key steps in maintenance.

Final Thoughts

Panel manufacturing might seem technical, but it plays a huge role in the safety and efficiency of any facility. Whether you’re setting up a new industrial unit or upgrading an old system, choosing the right panel manufacturer is one decision you can’t afford to get wrong.

With PIMA Industrial, you’re not just getting a product—you’re getting peace of mind, industry-leading quality, and a partner who understands your needs.

So, if you’re looking for a trusted panel manufacturing company or want to work with the best panel manufacturer in Ahmedabad, we’re just a call away.

Ready to build your panel the right way? Contact PIMA Industrial today!

Leave a Reply